Hiner-pack have many years of design,manufacturing experience in the field of JEDEC trays.We have produced a full range of JEDEC style trays for many customers who are specialized in semiconductor packaging and test.

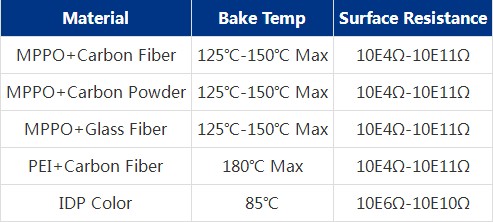

Hiner- pack is committed to the development and design of the most advanced JEDEC trays,company is equipped with advanced mould processing and injection molding equipment,and a variety of testing equipment to ensure product quality, JEDEC trays designed and manufactured by Hiner- pack could provide IC and IC module with completely different electrostatic level protection and convenient transportation approaches. A number of materials can be selected to meet customer's temperature-resistant baking requirements.

Designs conforms JEDEC international standard, and has strong versatility.

Optimal product design,can provide a variety of packaging IC with protection and while reducing transportation costs.

V type tray designs, with added protection for IC substrate edge ball placement.

A variety of materials for customers to choose from to meet your ESD and process requirements.

Support for non- standard format customization.

BGA,QFN,QFP,PGA,TQFP,LQFP, SoC SiP etc. All packaging methods are available. Can be customized based on customers requirement(e.g: ESD property, Baking Temp,Baking Time).

| Material |

Bake Temp |

Surface Resistance |

| MPPO+Carbon Fiber |

125℃-150℃ Max |

10E4Ω-10E11Ω |

|

| MPPO+Carbon Powder |

125℃-150℃ Max |

10E4Ω-10E11Ω |

|

| MPPO+Glass Fiber |

125℃-150℃ Max |

10E4Ω-10E11Ω |

|

| PEI+Carbon Fiber |

180℃ Max |

10E4Ω-10E11Ω |

|

| IDP Color |

85℃ |

10E6Ω-10E10Ω |